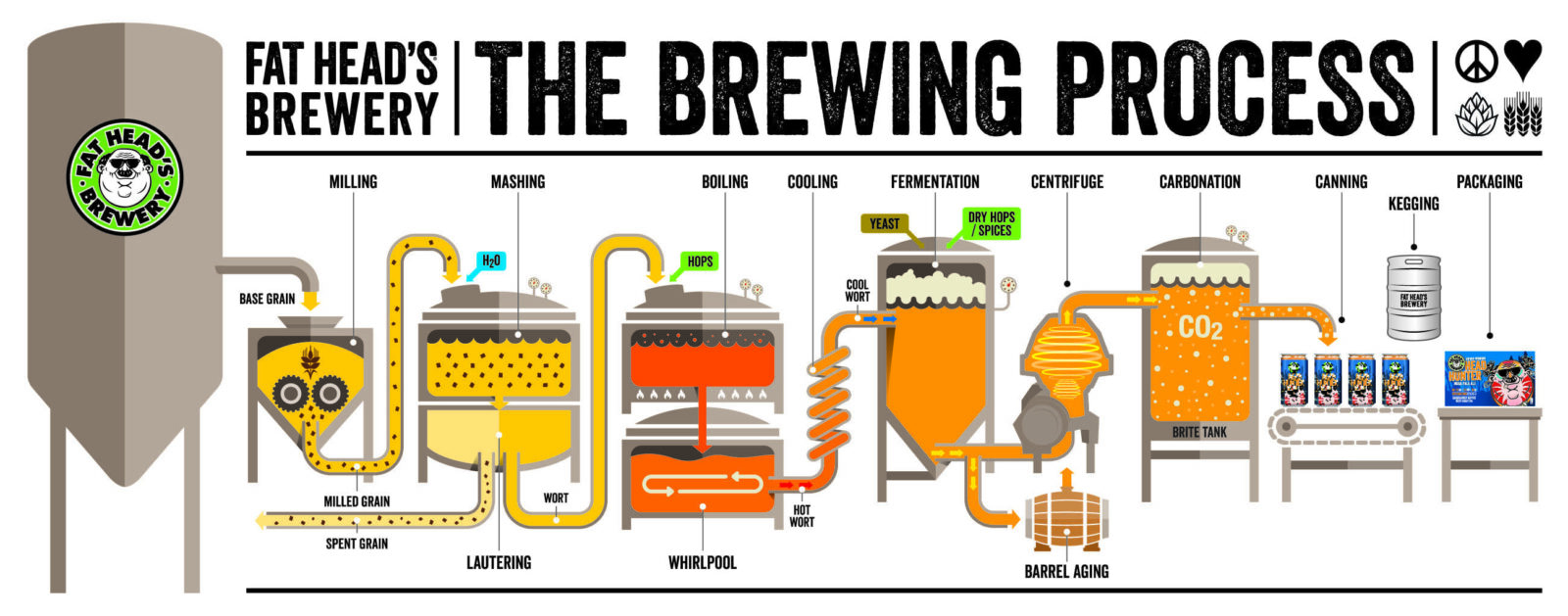

It starts with the malt! Milling, Mashing, and Boiling

To start the process, base and specialty malts are milled to open the husks and expose the starch inside. This grist is then soaked in water at varying temperatures. The natural enzymes from the malt break down the starches and convert them into sugars, which becomes the food source for yeast to ferment into alcohol and CO2 later in the process. The mash is heated to stop enzymatic activity, then lautered (or separated) to remove the sugary liquid from the grist.

This liquid is then boiled with hops to become wort. Boiling sterilizes the wort, concentrates the sugar content, and utilizes the hops to impart bitterness, flavor, and aroma. The timing of the addition, and the duration of the boiling, determine the hoppiness of the final brew.